Installation and Retrieval of Mooring Equipment

Delmar has safely and efficiently installed a wide range of mooring system options including conventional, insert component, and preset systems.

Conventional

Many semi-submersible drilling rigs are fitted with chain, wire, or a chain/wire combination mooring system. These systems are commonly installed with drag anchors.

In these, the mooring component is deployed from the rig while the anchor boat pays out chase wire, maintaining sufficient bollard pull to ideally keep line components off bottom throughout the process. Once all line component is paid out, the anchor boat provides a final stretch before cutting power, allowing the anchor to set.

Insert Component

When a rig’s onboard mooring system is insufficient for a proposed water depth, the length of the mooring legs can be increased with the addition of extension component in the mooring leg(s). This methodology is similar to a conventional installation, with the added step of a second anchor boat adding component into the line prior to the line being stretched and set.

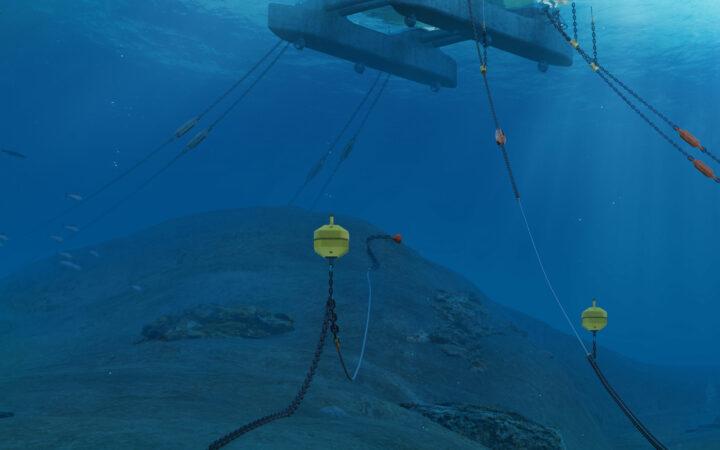

Preset

For numerous reasons, anchor boats can pre-install a mooring system for the drilling location. Anchors, chain, wire, and polyester can be installed on the location before the rig arrives, off critical path time of rig operations.

Polyester

Synthetic mooring components like polyester aid in ultra-deepwater applications where a rig’s self-contained steel system is too heavy. The elasticity of the polyester provides stretch to dampen second order motions induced by severe environments, improving rig performance. At the same time, the elevated catenary induced by using a lighter polyester component provides better stationkeeping, allowing the vessel to maintain tighter watch circles compared to a chain or chain/wire system.

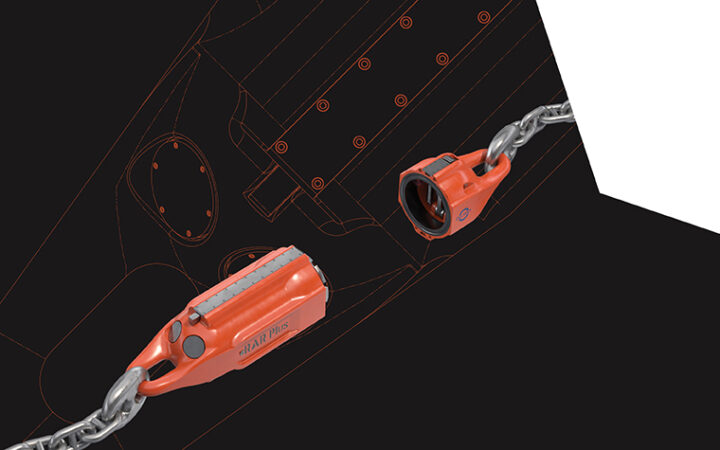

OMNI-Max®

The OMNI-Max is a multi-directional, self-penetrating, gravity installed anchor. Relatively small in size, this anchor offers high capacity and out-of-plane loading capabilities not found in other traditional anchoring foundations. With its rotational arm, the anchor is capable of maintaining sufficient capacity with any pull direction—360° around the axis of the anchor. This unique feature increases station-keeping reliability, reducing subsea risk due to anchor failure during storm events. Anchor penetration can also be immediately verified after each anchor installation, confirming the expected soil conditions at each anchor location.

Suction Anchor

Suction anchors can be used for mooring systems looking to mitigate the potential for anchor drag. The anchor self-embeds under its own weight before water is pumped out of the top of the caisson. This process is simply reversed to recover the anchor.