Geotechnical and Structural

Delmar Systems offers a variety of open water and MODU-assisted subsea installation capabilities. We offer our clients an extensive list of off-the-shelf commercial, as well as Delmar-proprietary, tools and the equipment needed for your projects. If you have a need for a specialty piece of equipment that does not exist, we work with you to help design a unique cast, fabricated, or forged piece of equipment that is needed for your project.

The Delmar Engineering Anchor Program (DEAP™) is an anchor analysis tool that predicts the performance of drag, VLA, Omni-max and suction pile anchors in various soil types. The performance includes the influence of the mooring line in the soil, the load versus uplift angle at the mud-line intersection point, and the specific anchor parameters (fluke angle, fluke area, etc.). Catalogue anchor capacity values for drag anchors do not account for the system-specific mooring line configurations. Ultimate drag anchor capacity (maximum it can achieve) is when the fluke becomes horizontal (or generally parallel with the seabed). API RP-2SK’s anchor uplift angle-based reductions to (catalogue) capacities does not apply to the results from a DEAP analysis since they are already included within the program’s methodology.

DEAP™ was jointly developed by Delmar and Texas A&M University’s Geotechnical Department. DEAP™ is an analytical tool which is prefaced with the discussion in API RP-2SK’s Appendix D in Section D.10. DEAP™ utilizes published bearing factors and those from scaled model and full-scale field testing for different anchors. Soil properties are either provided as site-specific from the client or an upper/lower bound approach based on our regional soil database is utilized.

Tool and Special Equipment Design

Delmar has developed numerous patented equipment designs while maintaining the highest standards of engineering and fabrication qualifications. When the industry does not offer the tools necessary for your projects, or when we think a safer and more efficient design is possible, Delmar designs specialized equipment and tools for the job. Examples of past equipment we have developed includes both on-deck and subsea anchor-handling equipment, quick release devices, subsea connectors, anchor foundations (OMNI-Max and pile anchors), A-frames, wire and rope spooling units, synthetic rope handling equipment, and various other unique tools and handling devices.

In addition, Delmar has designed mooring components, such as the patented Delmar Subsea Connector (DSC), patented Delmar Quick Release (DQR), Delmar Chaser Stopper (DCS), the patented RAR Plus, submersible buoys, buoy swivels, chain chaser stoppers, and wide-body chasers.

Through an efficient combination of Delmar’s extensive offshore operational experience and technical capabilities, Delmar can assist in designing new anchor handling and other offshore devices and procedures.

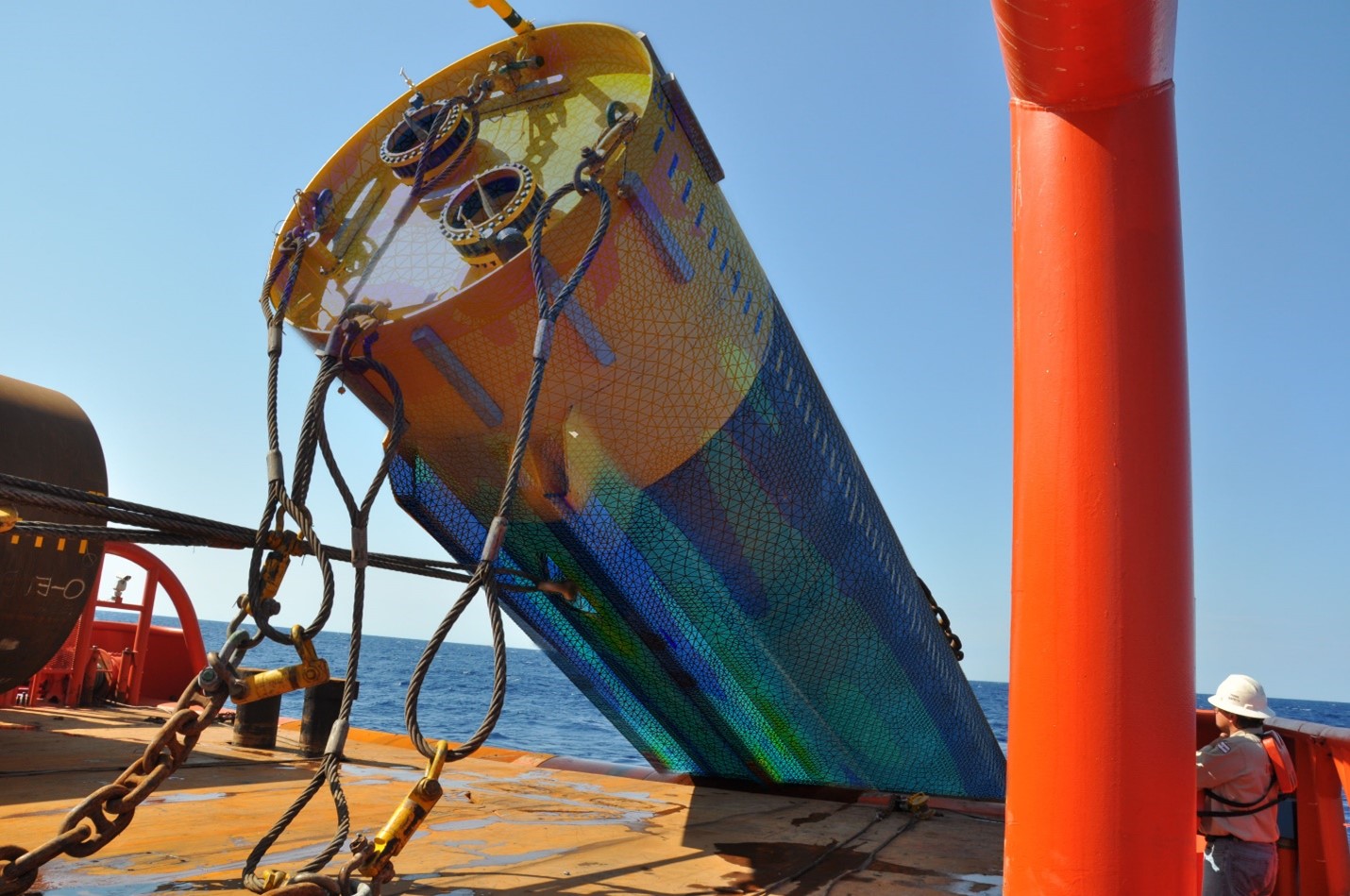

Suction Pile Design

Delmar is the industry leader in suction pile design and installation. With a track record that spans more than 500+ installations and retrievals, Delmar has an unmatched database of suction pile data. The engineering group uses the suction pile database to efficientlty design new suction piles; the database takes much of the guesswork or margin out of pile design that other firms would have to include. Delmar-designed suction piles have enjoyed a 100% success rate largely due to our data collection and structured design process.

Delmar uses several different techniques to analyze its suction pile foundations. The most sophisticated includes Finite Element Analysis of the pile structure, the surrounding soil, and the soil plug inside the pile. Depending on the application and previous analyses, more simplified modeling techniques may be used. Delmar has built an extensive database for mooring pile anchors for use in the Gulf of Mexico.

Delmar has also developed the tools necessary to make suction pile anchors a safer, more cost-effective anchor foundation option for both temporary moorings and permanent floating production facilities. As Delmar continues to install and retrieve suction piles, Delmar remains committed to further enhancing this technology.

Rapid Prototyping

Delmar is able to create 3-D models of its tools, anchors, and piles in a very short period of time for client and internal testing or presentation purposes. The models are an excellent way to showcase our products and help clients better understand the technology and its applications.