Permanent deepwater mooring and in-line tensioning

Delmar Systems was contracted to supply the STEVMANTA® vertical load anchors and STEVADJUSTER® in-line tensioners for the turret-moored FPSO Firenze at the Baleine field offshore Côte d’Ivoire, West Africa, in 1,015m water depth.

The Baleine field is located ~80km southwest of Abidjan, in Ivorian deepwater blocks CI-101 and CI-802 and is the largest hydrocarbon discovery in the country since 2001. It is operated by Eni Cote d’Ivoire, a subsidiary of Italian multinational Eni (90% interest), and Ivorian sate-owned national oil and gas company Petroci (10%). The field is estimated to hold ~2.5 billion barrels of oil and ~3.3 trillion cubic feet of gas reserves. Phase 1 of the field development saw the installation of FPSO Firenze at the site, which has a storage capacity of 700,000 barrels. It was previously deployed in the Aquila field, also operated by Eni, offshore Italy, until 2018.

The vessel had been upgraded to treat up to 15,000 barrels of oil and 25mcf of associated gas per day to support initial production at the Baleine field, with produced oil exported via shuttle tankers and gas piped to a refinery onshore at Abidjan.

DEEPWATER MOORING SYSTEM WITH UNLIMITED UPLIFT CAPACITY

The turret mooring system is comprised of 95mm diameter studless R4 chain and 119mm diameter polyester rope. In extreme load cases there is potential for uplift at the seabed, so Delmar Systems designed and supplied 11sqm STEVMANTA® for each of the eight legs, complete with shear pin angle adjuster suitable for single line deployment and installation. Design pull-out capacity was 314mT, in accordance with ISO 19901-7.

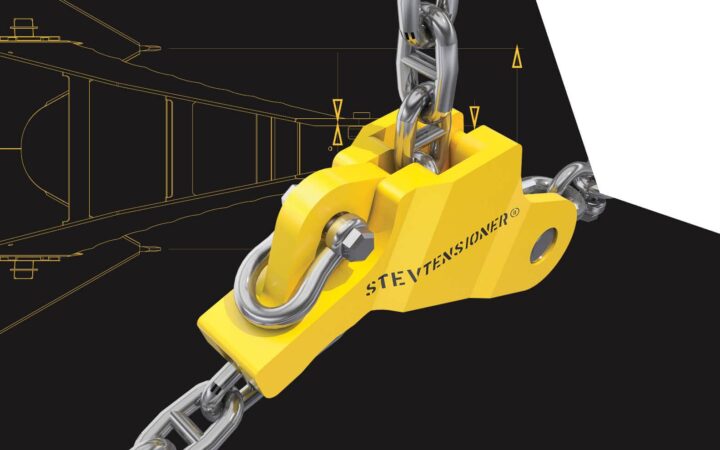

To enable line length adjustment and tensioning of the mooring, an in-line tensioner was included in the design to operate on the ground chain section of the mooring. For this, Delmar Systems designed and supplied our patented Mk2 STEVADJUSTER® to suit the 95mm chain. Both the anchors and tensioners were manufactured and tested to DNV standards in the Netherlands to a tight delivery deadline and were shipped to Abidjan in early 2023.

ENSURING MOORING PROJECT SUCCESS

The anchors and ground chains including the STEVADJUSTER®'s were pre-installed in April 2023 from the anchor handling vessel Olympic Zeus. All the STEVMANTA®'s were successfully embedded with 165mT bollard pull to break the shear pin and trigger the anchor into its normal loading configuration. Drag lengths averaged 21m, right in the middle of the predicted range, and estimated burial depth was 16m below mudline.

HOOK-UP AND TENSIONING OPERATIONS

The FPSO arrived on site in August 2023 and was successfully hooked up to the pre-laid mooring legs. The STEVADJUSTER®'s were used in turn to pretension each leg to the target load, this operation typically taking 4 hours on average per leg, using only a single vessel. First oil was produced after systems commissioning later in 2023.

FEATURES

Client: Saipem/Eni

Application: FPSO

Location: Offshore Abidjan, Ivory Coast

Water depth: 1,015m

Period: 2023

Products: 9 x 11sqm STEVMANTA® and associated rigging, 9 x 95mm Mk2 STEVADJUSTER®

Services: Provision of supervisory personnel offshore during pre-lay and hook-up