VERSATILITY FOR TAUT LEG SYSTEMS

Marine operations related to offshore exploration and production are moving fast into deeper water, pushing the operational limit of existing equipment. On floating units the weight of the mooring system is a limiting factor and weight savings are achieved by using different configurations and lighter materials.

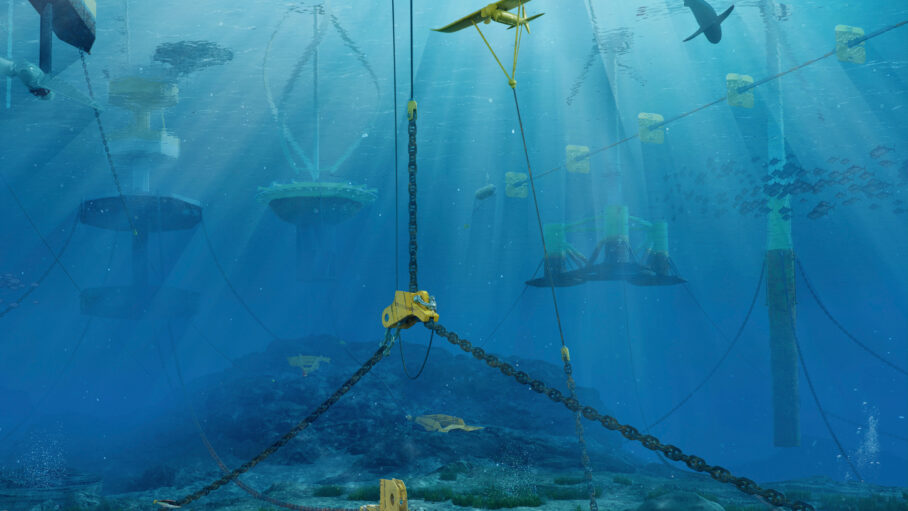

Taut leg mooring

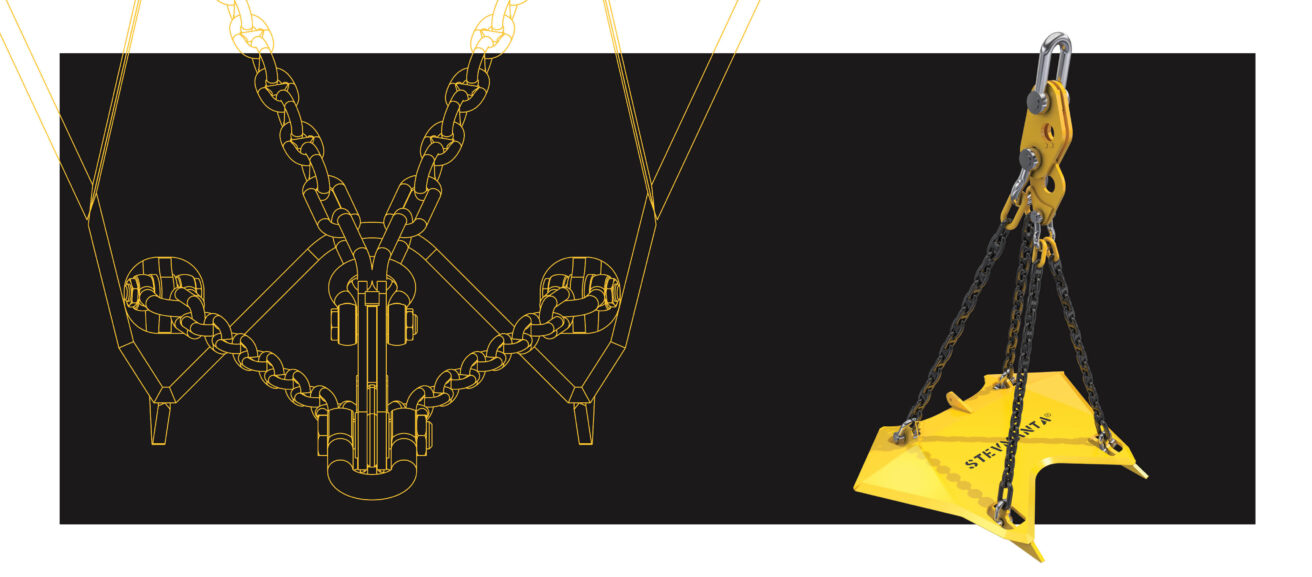

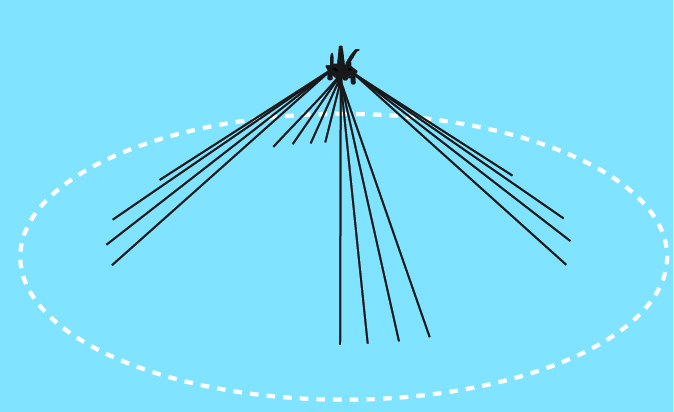

One way to achieve weight savings in a mooring configuration in (ultra) deepwater is to use a taut leg mooring. The mooring lines are much shorter than in a conventional catenary mooring, thus saving weight. In the taut leg mooring the unit’s movements are absorbed by the flexibility in the mooring line, typically provided for by light weight polyester ropes, so that even further weight savings can be achieved. As the anchor line arrives at a 45 degrees angle at the seabed, a Vertical Load Anchor (VLA) is required. Vryhof’s STEVMANTA® has in the last decade been applied around the world, used on permanent systems as well as semi-permanent and mobile.

Vertical Load Anchor (VLA)

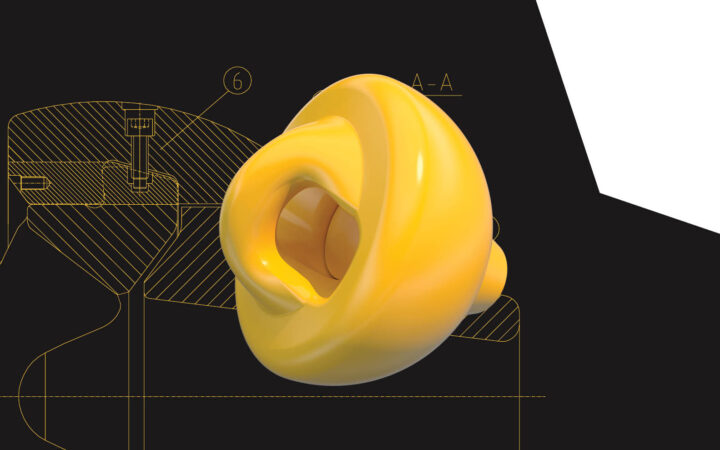

The STEVMANTA® was designed to be installed in the same way as a drag anchor. A unique and patented system makes the anchor change from installation mode to vertical mode which results in an immediate increase of holding capacity of up to 3.5 times the installation load. It is the lightest and smallest deep water anchor available on the market. A full VLA mooring system can be installed by one anchor handling vessel in a fraction of the time required for the installation of other anchored systems.

Permanent versus mobile

Mobile Drilling Units (MODUs) have different anchor requirements than permanently moored systems. The permanent STEVMANTA® is designed to meet the strength and fatigue requirements of a project. The shank is replaced by 4 wires to ensure extreme low installation resistance and thus deep penetration. The anchor is usually not retrieved. Anchors for temporary moorings need to be more robust to withstand repetitious handling, installation and retrieval. The shank usually consists of chain instead of wire rope. For retrieval, pulling the anchors with a fraction of the installation load suffices. Once the chains have been connected again, the anchor is ready for re-installation.

The MODU advantage

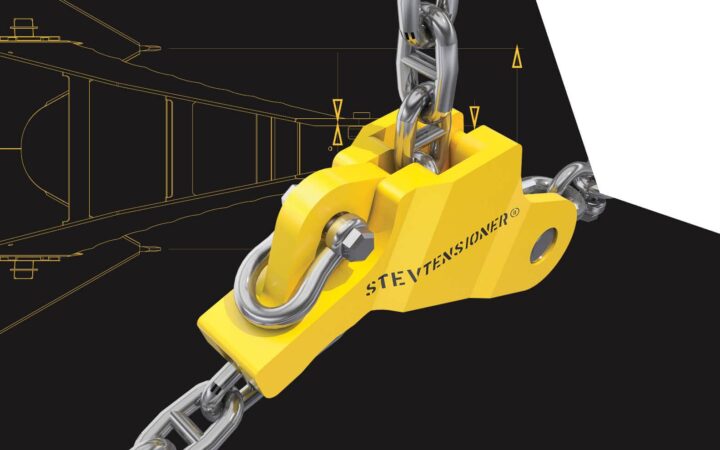

The STEVMANTA® is suitable for use on a rig and even allows the rigs to be tautleg moored. With a maximum of 100 mT winch pull required the STEVMANTA® can be deployed from a rig’s existing mooring system and chain or wire inserts are no longer needed. The installation of the STEVMANTA® is conventional and simple, as is its retrieval. The benefits are clear. These weight reductions directly benefit the rig’s payload capacity, extending its operational capacity to much deeper water.