REPLACING CUSTOMISED ANCHORS ON EXISTING MOORING SYSTEM

At the end of 2014, Vryhof Anchors was contracted to deliver four new customised 20 tonnes STEVPRIS®Mk6 anchors and to conduct the installation of two of these as replacement of two drag anchors on an existing mooring system of a Floating Production Unit (FPU). The original system was installed back in 1996 and consisted of 12 STEVPRIS®Mk5 anchors ranging from 20 - 24 tonnes and 12 legs of 3 7/8 inch chain.

The reason for choosing the robust STEVPRIS®Mk6 has everything to do with the extreme holding power of this anchor type due to wider fluke and deeper penetration. The anchor’s geometry also accommodates the widest range of soils possible. For this particular project, the anchors held tension over 325 tonnes in medium to soft silty clay.

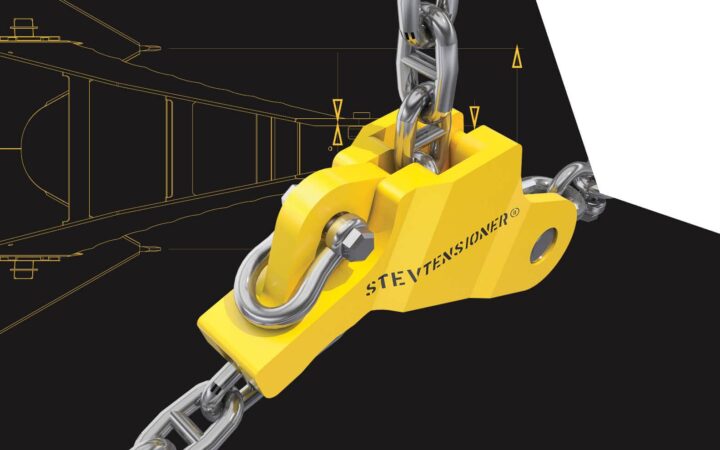

To install the two STEVPRIS®Mk6 anchors at a water depth of 140 - 190 metres, Vryhof Anchors used the STEVTENSIONER® VA1000, a chain shortening clutch with a reaction chain connected on one side and the active mooring chain running through it. The use of this compact device for subsea tensioning offers significant time and cost benefits as it reduces the required installation load by up to 60%.

As a result, mooring installations with high loads can be performed from a single anchor handling vessel. In this case, the 325 tonnes installation load was achieved with only 160 tonnes at the vessel. STEVTENSIONER®‘s also take up far less working area on the sea floor enabling installation of drag embedment anchors in otherwise space restricted areas.

The main risk that was involved in this ‘replacing’- project was that one of the mooring lines was too close to the FPU’s floating gas are to be worked on safely without shutting down production. Vryhof Anchors had to get the job done right first time and within the most economic time frame.

Thorough engineering preparation work was needed to calculate every detail of the installation with the eventual objective of making the replacement of the two anchors faster, easier and safer. Normally a job like this could take up to 12 hours but Vryhof Anchors managed to install each anchor within six hours. An achievement that marks another sample of the company’s problem-solving ability.