The industry standard

Due to their versatility STEVPRIS®Mk6 anchors serve a wide range of mooring applications. Although the large majority serves the mooring of offshore units such as drilling rigs, FPSO's and SPM buoys they are also widely used for various dredging, crane and pipelay vessels. Furthermore STEVPRIS®Mk6 anchors are employed worldwide for the mooring of Floating Wind Turbines.

The range of water depths in which the offshore industry operates is expanding fast. The requirements for the mooring of floating units ask for a focus on less weight, higher strength and ultra high holding power, while mobile units also demand high versatility and HSE-friendliness. In these times of focus it seems a new anchor is being developed for each specific application. The majority of offshore projects however meet variables in water depth, soils and operational conditions, in all asking exactly the opposite: a generic anchor that suits all purposes.

The most used anchor

The STEVPRIS®Mk6 is just that. Well over 8,000 units were employed over some 3 decades. Since the introduction of its 6th generation more than 2,000 units were sold, making it the most successful anchor in the company’s history. The STEVPRIS®Mk6 design combines the best of 3 worlds: the feedback from numerous anchor installations, a fluke design derived from the STEVMANTA® and the inherent robustness of the STEVPRIS®Mk5 shape. The STEVPRIS®Mk6 is superior to all its predecessors on all of its characteristics.

A balanced design

The anchor’s geometry provides an extreme high weight/strength ratio. The fluke shape minimizes soil disturbance and its large surface provides the huge holding power that is well in excess of 30% more than that of any other drag anchor today. The design is type-approved by major Classification Authorities.

Uplift capability

STEVPRIS®Mk6 has superior uplift capability. On a case to case basis uplift is allowed of 5 degrees in intact condition and 10 degrees in damaged condition. API rules suggest an uplift of 20 degrees, proven in tests to be possible without losing holding power. The uplift capability significantly increases the range of water depths in which rigs can operate on the same anchor spread.

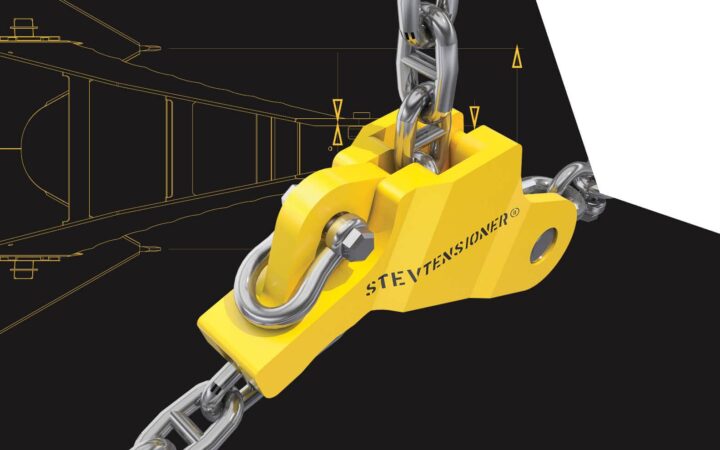

Easy handling & Installation

Some of the STEVPRIS®Mk6 key improvements derive directly from a drilling operator’s wish list but its generic character suits evenly well for permanent moorings, dredging plant and marine construction applications. The widely placed shank plates serve correct arrival at the AHV stern roller while the wide fluke provides stability on the seabed as well as during penetration. Placement of the shackle between the shank plates prevents interference with the chaser. The fluke angle can easily be adjusted to 3 different positions to match different soil conditions.

Easy retrieval

The shank head improves ‘locking’ the chaser before breaking the anchor loose. Likewise it holds the anchor steady during hauling and with the chain or line ‘held’ in the fluke V-shape the anchor orientation is locked for easy racking or decking. Overall, the compact sleek design allows easy handling on deck and proves HSE-friendly.