TESTING ANCHORING PROCEDURES BY USING STEVTENSIONER® WITH ACOUSTIC TELEMETRY

Vryhof Anchors was contracted to provide Stevtensioning services and personnel to assist in testing anchoring procedures in the deep water of the Brulpadda 1AX project, some 180km south of Mossel Bay, South Africa.

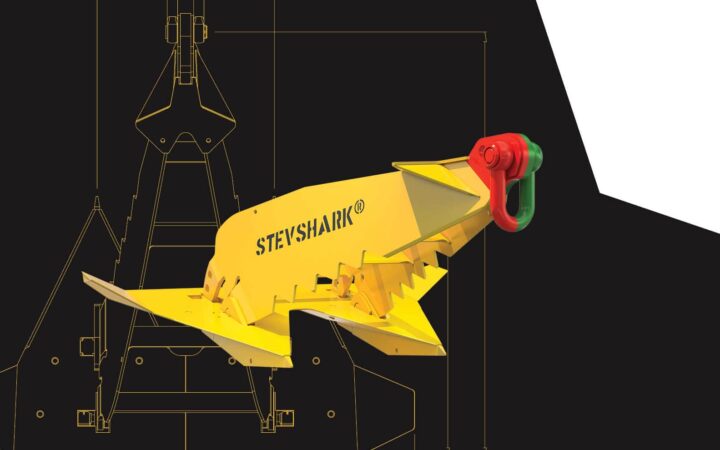

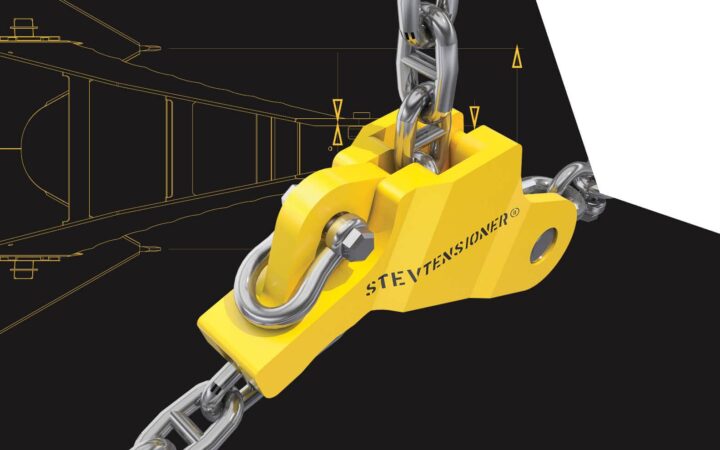

The purpose of the test at a water depth of 1,430m was to determine holding capacity of the seabed around the existing well head in order for a future return of a drilling rig to this location. Anchors used were two 16mT STEVSHARK® with 6.2mT ballast in the fluke, which were to be installed by cross- tensioning using a new performance optimized STEVTENSIONER® , equipped with acoustic telemetry for tensioning data. The design of the three different STEVTENSIONER®models is based on the principle that a vertical load to a horizontal string causes high horizontal loads. Typically to achieve the required horizontal pretension load at the anchor points, the vertical pulling force only needs to be 40% of this pretension. A repeatedly heaving up and slacking the STEVTENSIONER® in yo-yo action builds up the load in the mooring chain until the required tension is achieved.

Installation configuration

Two vessels were mobilised for the operation: the ‘Maersk Seeker’, assigned to bollard proof load the active anchor and then to undertake the Stevtensioning operations and the ‘Peridot’, for undertaking the laying and retrieval of the passive anchor.

The composition of the mooring lines was as followed:

Active line:

- 16mT STEVSHARK® anchor for improved anchor embedment performance with 6.2mT ballast in fluke

- 760m of 84mm chain

- 3x 185m= 555m 76mm pennant wire

- 4 shots = 610m of 84mm chain with slim line kenter links (for passing STEVTENSIONER®)

- Swivel

- 83mm working wire of vessel (2,200m for Bollard Pull)

Passive line:

- 16mT STEVSHARK® anchor with 6.2mT ballast in fluke

- 5 shots = 762m of 84mm chain including 1 swivel

- Bridle tail for anchor to working wire of the ‘Peri dot’ for lowering and retrieval of anchor. Anchor will remain connected to the ‘Peridot’ with this system

Retrieval wire STEVTENSIONER®:

- 83mm working wire of vessel, socket connected with 120t shackle to 120t shackle of the STEVTENSIONER®.

Setting of active anchor

At first the active anchor was deployed vertically to the seabed and by slowly dragging it into the required direction the anchor was correctly positioned for installation. Two tensioning tests using the vessel bollard pull were conducted with different pay outs of the work wire, both using a bollard pull of 190t. The first test was with 2,200m of wire (resulting in 90t at the anchor), and second test with 900m of wire (resulting in 170t at the anchor). After the setting of the anchor, the working wire was retrieved until the tensioner chain was on the working deck again.

Passive anchor and STEVTENSIONER® deployment

After connecting the STEVTENSIONER® to the chain, the passive line was passed over from the ‘Peridot’ and connected to the passive side (shackle at the load cell) of the STEVTENSIONER®. Then the ‘Peridot’ deployed the passive anchor and some shots of chain, after which the STEVTENSIONER® was deployed over the stern roller of the ‘Maersk Seeker’.

Acoustic information

The transducer of the mobile acoustic system has been positioned directly next to the side pole of the positioning system. This provided the best option for this dunking transducer not to be subjected to the >3kts current ow at the test location, eliminating free hanging over the side as an option. Being only 1.5m below the keel of the vessel noise and bubbles were significantly present, irregularly interfering with data communication. The telegram has most security on the positioning data which includes depth. Additional telemetry like the STEVTENSIONER® pitch and strain are therefore more likely to be disturbed by the acoustic environment. Depth reading is based on the distance between the transducer at the end of the pole and the modem on the STEVTENSIONER®. This ‘near vertical’ distance proved very reliable as depth reading.

Conclusion

The primary goal of the STEVTENSIONER® has been achieved during this mission: provide the tension necessary to show sufficient holding power at the Brulpadda 1AX location. The STEVTENSIONER®with acoustic telemetry has proven its functionality. The acoustic telemetry, given good conditions, is capable of communicating tensioning data to the topside station providing valuable insight in the process at depth. Especially the accurate depth reading proves a great help in controlling the tensioning process without the help of a ROV. The pitch reading proves useful for information about the locked/unlocked state of the STEVTENSIONER®. The force provided by the strainstall load pin monitors the force at the tensioner and provides ample evidence of the installation force. Also the geometry of this new STEVTENSIONER® is very well matched for the 84mm chain, providing good deck handling of the chain at low tension and good sliding and locking while hanging on the chain.

FEATURES

Client / Operator: TOTAL E&P SA

Location: 80 km south of Mossel Bay, South Africa

Period: February 2016

Main Contractor: Vryhof Anchors

Services: Stevtensioning services and personnel