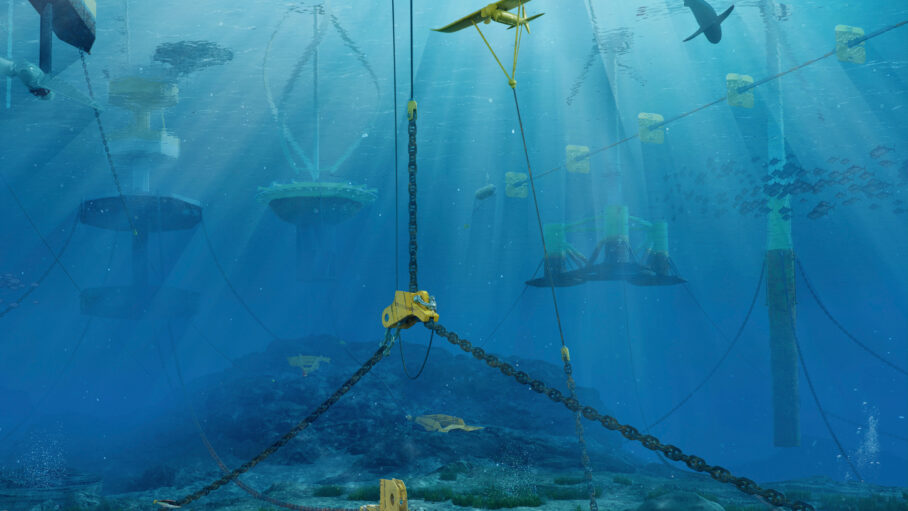

Emergency moorings for Serpentina FPSO offshore Equatorial Guinea

ExxonMobil contracted Delmar Systems to develop the temporary emergency moorings for FPSO Serpentina offshore Equatorial Guinea in the Zafiro-Eagle field, West Africa.

Delivery of the full temporary EPCI package for the replacement of all 9 mooring lines from the turret uni-joints to the anchors had to take place in a limited time frame and at a competitive rate. Delmar Systems managed to deliver and install the complete package within a span of 7 months.

All 9 mooring lines were optimized for the highest level of survivability for sudden squall storm events while maintaining the allowable production riser offset limits.

Fully coupled time-domain dynamic analyses were performed to verify the survivability in sudden site-specific squall storm events.

Site-specific geotechnical analysis of the OMNI-Max anchors was performed to verify installation penetrations and holding capacity in the Zafiro-Eagle field soils.

Delmar Systems procured the specified equipment for each mooring line and mobilized the equipment for shipment to Mobile Equatorial Guinea’s base in Luba.

Installation engineering was performed to develop the detailed installation procedures for the OMNI-Max anchor installation, pre-installation of the mooring lines, and hook-up to the FPSO top chain at the turret padeyes.

The installation methodology was tailored to utilize existing the Anchor Handling Tugs already on a long-term contract in the field, as well as limitations of the FPSO turret pull-in winch.

ExxonMobil then contracted Delmar Systems to design the permanent replacement for the temporary FPSO moorings, that solves all issues of the original system. Numerous iterations were performed to account for trenching predictions, mooring and riser fatigue, and turret pull-in winch capabilities.

Delmar Systems developed detailed line configurations and installation methodologies, including the design of specialty tools to aid in manual work in the FPSO turret.

Finally ExxonMobile contracted Delmar Systems to go offshore and perform QC on behalf of ExxonMobil to ensure that the installation contractor installed all equipment within tolerances.

Delmar Systems also specified chain cut lengths to account for as-installed anchor locations and ensure load-sharing and as-designed global system performance.

All measured line angles for the as-installed mooring system were found to be within 0.1-degrees of design upon completion.